The Franciacorta method, recognized in DOCG regulations since 1967, is the method identified as “classic” used to obtain the world-renowned wine carrying its name. To produce a Franciacorta DOCG it is necessary to start from rigorous selection of the grape variety. In fact, the Franciacorta method foresees the exclusive use of the noble Chardonnay, Pinot Nero and Pinot Bianco grapes, the latter in a percentage of no more than 50%. Recently, the parterre of vines for the Franciacorta method has seen its rows enriched by the introduction of Erbamat. This is an ancient Brescian strain, present in the Garda area and in Franciacorta, a variety which until recently had seemed totally forgotten. Finally rediscovered, Erbamat has officially been entered in the ampelographic composition of Franciacorta DOCG, although use is allowed only in a maximum percentage of 10%.

These grapes result from the richness of the Franciacorta district. Here the vineyards have an estimated yield of 120 quintals of grapes per hectare. Moreover, to underscore more clearly the excellence of this product, the grapes are harvested exclusively and obligatorily by hand, according to the year between the first ten days of August and the first ten days of September. With masterful skill, the precious bunches are gathered, deposited in trays and transferred to the wine cellars to start the wine-making process known worldwide as the metodo Franciacorta. Each vineyard is harvest separately and the grapes, on arrival in the cellars, are tipped onto conveyor belts which take them to the press. Here the bunches are delicately pressed to obtain what is technically known as the mosto-fiore (flower must).

• THE FRANCIACORTA METHOD •

In purest Franciacorta tradition,

before all

-

SELECTION (the grapes, the harvest, the pressing)

-

TIRAGGIO

Once assembled the cuvée base is ready for draft operations, a technical term which defines the bottling operation, one step in the Franciacorta method. The draft consists essentially in favouring a second fermentation of the base wine by adding sugar (cane or beet) and suitably selected yeasts. Usually for each litre of wine, 24 grams of sugar are sufficient to develop the correct pressure inside the bottle to obtain a product in compliance with the Franciacorta method.

The bottle of wine is generally closed with a crown cap with a special lid (technically known as a bidule) used to collect the sediments that form throughout the next phase up to the pouring off or disgorgement (dégorgement).

-

SECOND FERMENTATION

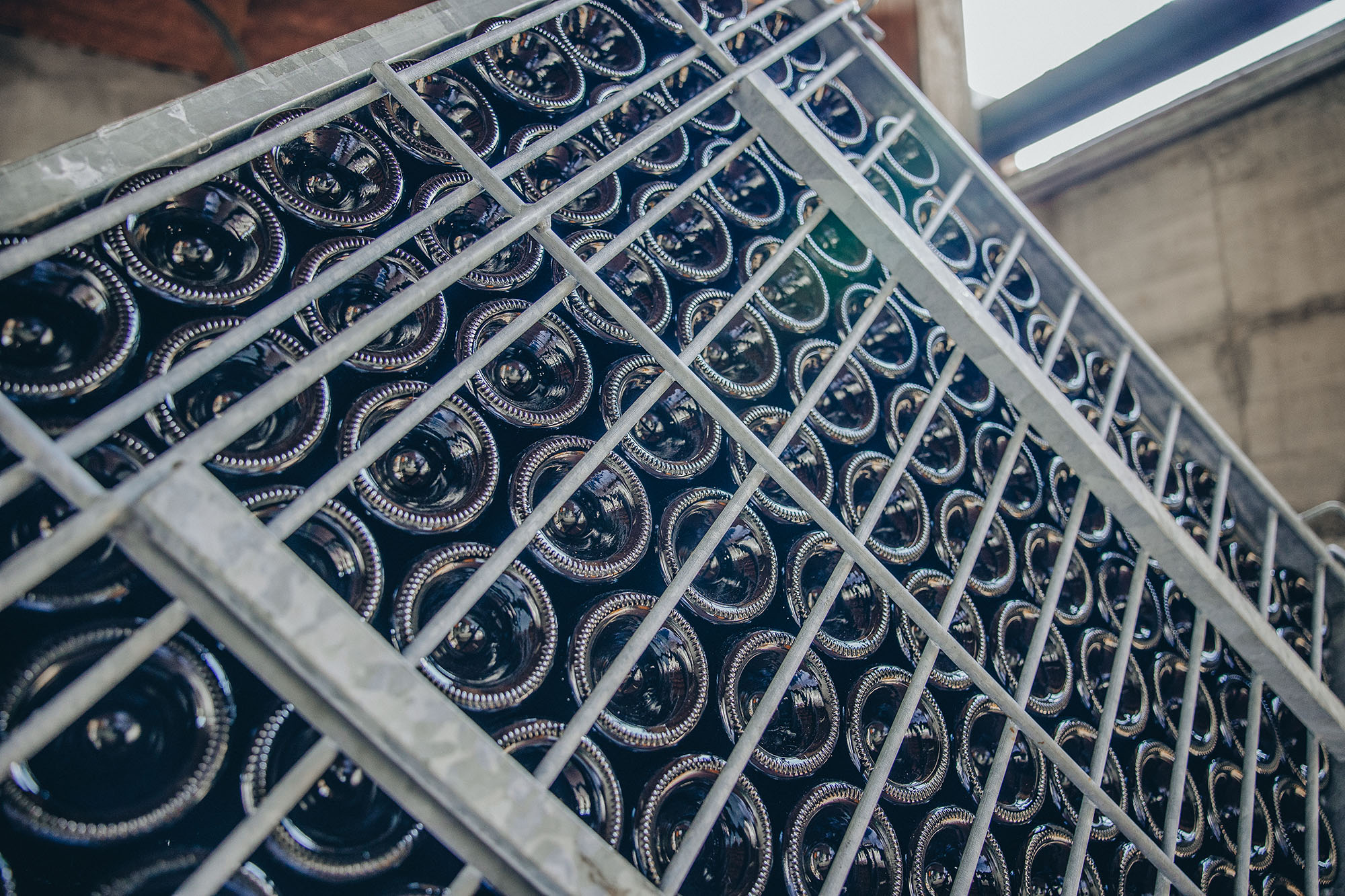

At this point the precious bottles, promise of a new year of Franciacorta DOCG, are transferred to cool dark cellars, stacked in horizontal position inside the traditional chests but also with preformed plastic sheets. They have to remain in this position for at least 18 months up to a maximum of 60 months (according to the type of wine required) during which the interaction between wine, yeasts and sugars will form a sediment which must be eliminated successively by means of other operations.

On completion of the fermentation phase, also known as “prise de mousse” because of the yeasts’ autolysis, or – that is – the refining process in terms of oenology, the Franciacorta wine reaches its particular sensorial profile while increasing in taste and quality. It is precisely during this resting phase in contact with the yeasts that we can distinguish the various types of Franciacorta DOCG obtained:

• at least 18 months for Franciacorta non millesimato

• at least 24 months for Franciacorta Satèn and Franciacorta Rosé non millesimato

• at least 30 months for Franciacorta millesimato, for Franciacorta millesimato Satèn and for Franciacorta millesimato Rosé

• at least 60 months for Franciacorta Riserva, for Franciacorta Riserva Satén and for Franciacorta Riserva Rosé.

-

REMUAGE/SHAKING

After completing the refining period in a horizontal position, the bottles are transferred to tilted stands, technically known as pupitres. In this new phase they are subjected daily to a specific operation called remuage or shaking. As the name suggests, this consists of a rotation of one eighth of a turn each day and, contextually, a progressive increase of the bottle’s inclination to facilitate the descent of the sediment with the fermenting yeasts towards the neck of the bottle. This operation, certified by the Franciacorta DOCG method, is done by highly specialized staff who are each capable of turning even up to 15,000 bottles a day.

-

DISGORGEMENT

Considering three or four weeks necessary for the sediment and yeasts to descend into the neck of the bottle, the next step is disgorgement. The bottles are removed from their tilted supports and placed vertically with their necks immersed in a refrigerating solution. Direct chilling causes the sediment and yeasts to solidify, creating a sort of frozen plug, easier to extract. Only at this point is the crown cap removed and thanks to the pressure created inside the bottle, the frozen sediment is expelled with the loss of only a tiny amount of wine.

-

LIQUEUR D'EXPÉDITION/DOSAGE SYRUP

The initial level of each bottle is restored by introducing the so-called dosage syrup or liqueur d’expédition, according to the French terminology used for the classic method. This consists of a mixture of the base wine and sugar in variable quantities, depending on the type of Franciacorta DOCG required (not dosed, extra brut, brut, extra dry, dry, sec, demi sec), used after the bottles have been disgorged in order to replace the volume of wine lost, even in tiny quantities. But it is not only a question of replacing the lost wine! Quite the contrary, the dosage syrup is what truly makes Franciacorta the international excellence it is. Every wine grower, every winery, jealously guards the recipe of their own liqueur d’expédition which represents their personal brand, making that particular wine unique and distinguishable from that of competitors.

-

ESTASI/REST

After disgorgement and addition of the liqueur d’expédition, the bottle is definitively closed with a top-quality cork, encapsulated and labelled: ready to be sold (for us only after an ulterior rest of at least 60 days in the finished bottle).

And here we are at the final phase: the metal cap is replaced with the characteristic cork anchored by the typical metal cage. Before being sold, every bottle must receive the Italian State seal to guarantee the origin and quality of the product as certified by the DOCG designation, Denominazione di Origine Controllata e Garantita (Controlled and Guaranteed Denomination of Origin). This seal carries a univocal alphanumerical code indicating the bottle’s capacity and the distinctive logo of the Franciacorta denomination, the classical crenelled “F”. In this way it is officially attested that the wine has passed all the qualitative tests and can therefore be recognized and marketed as a Franciacorta DOCG.

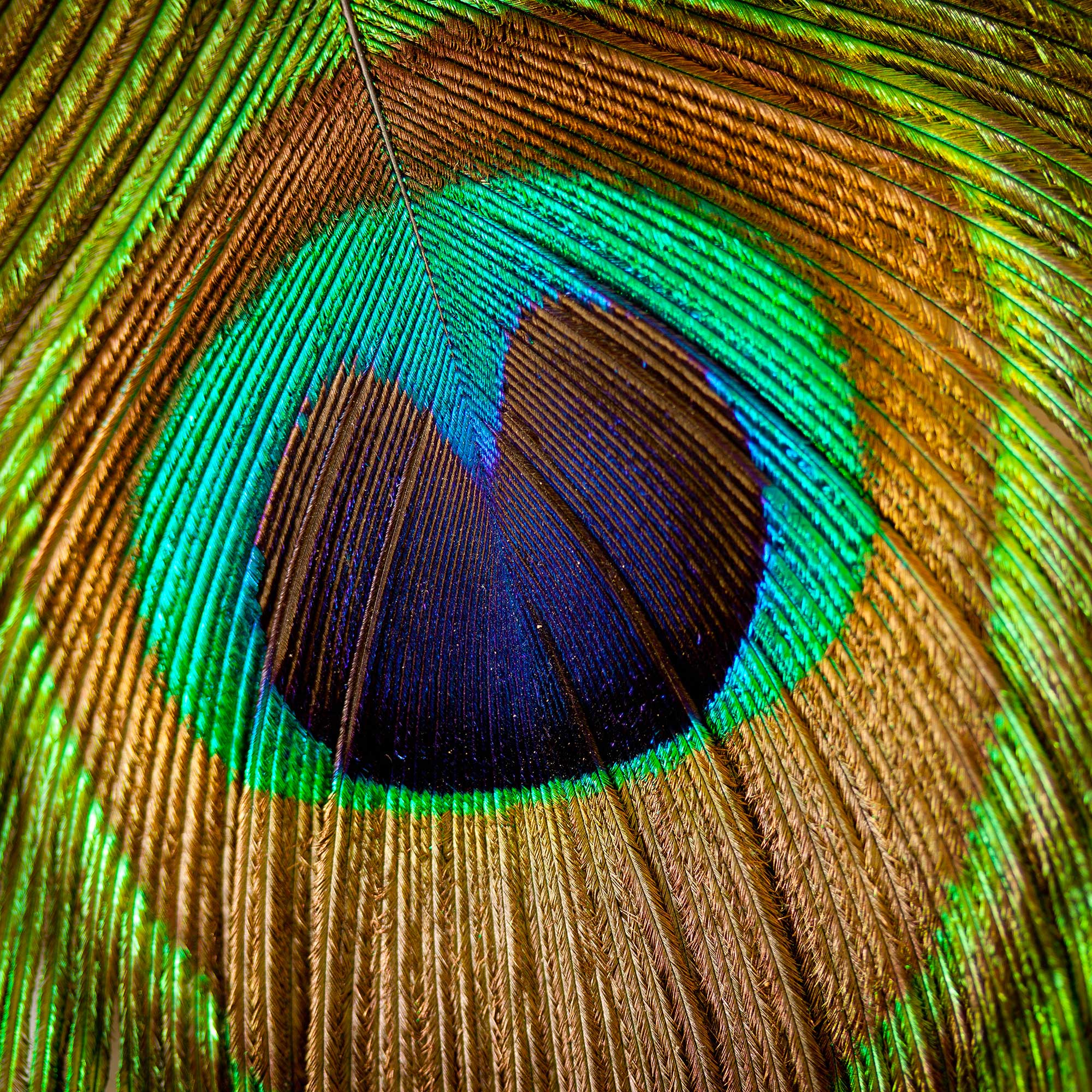

Pavò Franciacorta

Where all things good merge with the beautiful, this is where the story of Pavò Franciacorta begins.

A rich wine, sophisticated and surprising,

very much like a peacock’s plumage.

Pavò Franciacorta di Cristini Ettore & C. S.A.S

25050 Provaglio d'Iseo (Bs)

- +39 030 6854428

- info@pavofranciacorta.it

© Copyright 2022

Pavò Franciacorta di Cristini Ettore & C. S.A.S - P.iva 03735600987

Designed by Dimora Web Studio